-

appelez nous

0086-592-7161550 -

Envoyez-nous un email

ping@aotbattery.com -

Skype

ping@aotbattery.com

appelez nous

0086-592-7161550Envoyez-nous un email

ping@aotbattery.comSkype

ping@aotbattery.com

LiBF

4

La poudre est un sel de lithium largement utilisé dans

électrolytes de batterie au lithium

Il est composé d'acide tétrafluoroborique (BFF₄) et d'ions lithium et présente une bonne stabilité chimique et une conductivité ionique élevée.

LiBF

4

poudre

Il peut améliorer les performances de l'électrolyte des batteries au lithium, optimiser l'efficacité de charge et de décharge, et optimiser les performances globales de la batterie. Il reste stable dans des conditions extrêmes, telles que des températures et des pressions élevées, et est actuellement l'un des sels électrolytiques les plus utilisés dans les batteries au lithium.

C chimique P propriété

Stabilité

:

LiBF

4

La poudre présente une bonne stabilité chimique et thermique, ne se décompose pas facilement à haute température et conserve son intégrité structurelle et sa stabilité fonctionnelle dans des environnements supérieurs à 200 °C. Elle réagit difficilement à l'humidité et génère des gaz corrosifs, et sa décomposition ne produit pas facilement de substances toxiques.

Conductivité:

Sa forte conductivité ionique favorise la migration rapide des ions lithium dans l'électrolyte, améliorant ainsi l'efficacité de charge et de décharge de la batterie. Cependant, sa conductivité est légèrement inférieure à celle du LiPF.

6

, il peut fournir une conductivité plus stable dans des systèmes à forte humidité ou à solvants spéciaux, évitant ainsi la dégradation des performances causée par l'humidité ou d'autres impuretés.

Acidité:

C'est un acide de Lewis doux qui peut être utilisé dans certaines réactions organiques

Méthode de préparation

1. Méthode de réaction gaz-solide

Processus:

Placez la poudre LiF séchée dans un réacteur, introduisez du gaz BF3 sec et faites réagir à haute température (150-300 ℃) ou à haute pression.

Avantages :

Procédé simple, pas besoin de solvants, haute pureté du produit (jusqu'à 99% ou plus).

Défaut:

BF

3

Le gaz est hautement corrosif et toxique, nécessitant une étanchéité stricte de l'équipement ; il est sujet à l'encapsulation du produit LiF n'ayant pas réagi, ce qui entraîne une réaction incomplète.

Application:

Préparation à petite échelle en laboratoire ou scénarios de demande de haute pureté (tels que les électrolytes haut de gamme).

2. Méthode de la solution aqueuse (synthèse humide)

Processus:

Ajouter lentement des sels de lithium (tels que Li₂CO∝, LiOH) à H

BF

₄

solution aqueuse, ajuster le pH à neutre ou faiblement acide, agiter la réaction, filtrer, évaporer et concentrer, refroidir et cristalliser, et enfin sécher et déshydrater.

Avantages :

Conditions de réaction douces, disponibilité facile des matières premières, faible coût, adapté à la production industrielle à grande échelle.

Défaut:

Le produit est susceptible de contenir de l'eau cristalline, nécessitant un séchage à haute température (> 200 ℃), une consommation d'énergie élevée et peut se décomposer ; les solutions aqueuses sont sujettes aux impuretés résiduelles.

Application:

Production à grande échelle de qualité industrielle

LiBF4

(comme les électrolytes des batteries au lithium).

3. Méthode de la solution non aqueuse (méthode du solvant organique)

Processus:

La poudre de LiF est dispersée dans un solvant organique anhydre (tel que l'éther, le carbonate, l'acide fluorhydrique) et BF

3

du gaz est introduit ou H

BF

4

La solution est ajoutée goutte à goutte. Après réaction, elle est filtrée et séchée.

Avantages :

Éviter les interférences avec l'eau, faible teneur en eau et haute pureté du produit (jusqu'à 99,5 % ou plus), taux de réaction rapide.

Défaut:

Les solvants organiques (tels que le HF) ont une forte corrosivité et une forte toxicité et nécessitent des exigences opérationnelles élevées. La récupération des solvants est difficile, coûteuse et peut introduire des impuretés.

Application:

Préparation de haute pureté

LiBF

4

(comme l'électrolyte de batterie à l'état solide).

4. Méthode de réaction de double décomposition

Processus:

Les sels de lithium solubles (tels que LiCl) sont mélangés à des solutions aqueuses de tétrafluoroborate (tels que NaBF₄, KBF₄) pour générer

LiBF

4

précipité, qui est filtré, lavé et séché pour obtenir le produit.

Avantages :

Conditions de réaction douces, fonctionnement simple, adapté à une préparation rapide en laboratoire.

Défaut:

Le produit est susceptible d'adsorber des ions d'impuretés tels que Na⁺ et Cl⁻, nécessitant plusieurs lavages ; faible rendement, ne convient pas à la production à grande échelle.

Application:

Préparation à petite échelle en laboratoire ou démonstration pédagogique.

5. Méthode d'échange d'ions

Processus:

Une solution contenant du BF₄⁻ est passée à travers une colonne de résine échangeuse d'ions lithium (telle qu'une résine échangeuse de cations d'acide sulfonique), où Li⁺ se combine avec BF₄⁻, puis évaporée, concentrée, cristallisée et séchée pour obtenir le produit.

Avantages :

Séparation efficace des impuretés, pureté élevée du produit et degré élevé d'automatisation des processus.

Défaut:

Coût élevé de la résine, nécessitant une régénération ou un remplacement régulier, et coûts d'exploitation élevés ; Capacité de traitement limitée, adaptée à la production à petite échelle.

Application:

Préparation fine de haute pureté

LiBF4

(tels que les produits chimiques de qualité électronique).

Conditions de stockage

LiBF

4

La poudre est hygroscopique et doit être stockée dans un endroit sec, frais et bien ventilé, à l'abri du feu et de la chaleur. Maintenir le récipient hermétiquement fermé pour éviter toute humidité. La zone de stockage doit être équipée du matériel de lutte contre l'incendie et d'intervention d'urgence en cas de fuite.

UN application

Batterie lithium-ion :

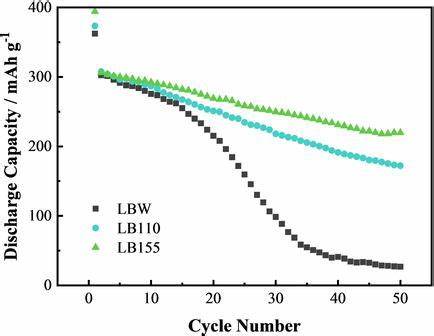

C'est un électrolyte important pour les batteries lithium-ion. En tant qu'additif électrolytique, il peut améliorer la structure de la couche d'interface de la batterie, réduire l'impédance de transfert de charge, optimiser les performances et la durée de vie de la batterie. Il peut également former une structure de solvatation stable avec le Li+, améliorer la capacité filmogène de l'électrolyte sur l'électrode et prévenir la corrosion des feuilles d'aluminium. À basse température, il présente de meilleures performances que le LiPF6 et peut être utilisé pour préparer des batteries lithium-ion longue durée à basse température.

Synthèse organique :

En tant que catalyseur largement utilisé dans les réactions de synthèse organique telles que l'estérification et l'alkylation, il présente une forte acidité et ne se décompose pas facilement, ce qui peut favoriser efficacement la réaction.

M marché

Du côté de la production, la production mondiale totale de poudre de tétrafluoroborate de lithium en 2024 s'élève à environ 32 000 tonnes, soit une hausse de 16,8 % en glissement annuel. Le marché mondial de la poudre de tétrafluoroborate de lithium devrait atteindre 1,86 milliard de dollars américains d'ici 2025, soit une hausse de 17,7 % en glissement annuel. La Chine occupe une position importante sur ce marché et devrait atteindre 65 % de sa part de marché d'ici 2025, avec une production atteignant 24 000 tonnes. À l'avenir, avec la maturité progressive de la technologie des batteries à semi-conducteurs, le champ d'application de

LiBF

4

La poudre devrait encore se développer.

Mots clés :

tel/Whatsapp: 0086-592-7161550

Scan to wechat: