-

appelez nous

0086-592-7161550 -

Envoyez-nous un email

ping@aotbattery.com -

Skype

ping@aotbattery.com

appelez nous

0086-592-7161550Envoyez-nous un email

ping@aotbattery.comSkype

ping@aotbattery.comLe processus de revêtement est un processus basé sur l’étude des propriétés des fluides, qui consiste à appliquer une ou plusieurs couches de liquide sur un substrat. Le substrat est généralement un film flexible ou un papier support, puis le revêtement liquide enduit est séché dans un four ou durci pour former une couche de film fonctionnelle spéciale.

The coating process of lithium-ion power battery electrodes has its own characteristics: double-sided single-layer coating is carried out sequentially, and most of the double-sideds coating machine on the market are also carried out sequentially on both sides; The wet coating of the slurry is relatively thick, generally ranging from 100 to 300 μ M; The slurry is a non Newtonian high viscosity fluid; Compared to general coating products, the precision requirement for polar film coating is high, which is similar to the precision of film coating; Coating substrate with a thickness of 4-30 μ M's aluminum or copper foil. At present, the lithium-ion power battery industry has widely adopted narrow slot extrusion coating technology to manufacture battery electrodes. Extrusion coating technology can obtain high-precision coatings and can also be used for high viscosity fluid coating. It is widely used in many fields such as flexible electronics, functional films, flat panel displays, micro nano manufacturing, printing, etc. In the actual process, the uniformity, stability, edge and surface effects of the coating solution are affected by the rheological properties of the coating solution, which directly determines the quality of the coating. Numerous researchers have devoted themselves to the study of coating windows through theoretical analysis, coating experimental techniques, fluid dynamics finite element techniques, and other research methods. Coating windows refer to the range of process operations that can achieve stable coating and uniform coating. They are influenced by three factors: (1) fluid properties, such as viscosity μ、 surface tension σ、 density ρ; (2) Geometric parameters of the extrusion die head, such as coating spacing H and die head slit size w; (3) Coating process parameters, such as coating speed v, slurry feeding flow rate Q. For extrusion coating, there is an upper limit and a lower limit of coating speed at a fixed flow rate, and the range between the upper and lower limits of coating speed is the coating window. The upper limit of the coating window is mainly affected by the stability of the coating liquid. For example, when the flow rate is insufficient or the coating speed is too fast, the coating liquid droplets begin to become unstable, which is prone to defects such as air infiltration and lateral waves. When the lower limit of the coating window occurs, if the flow rate is too high or the coating speed is too slow, the fluid cannot be carried away in time, and a large number of coating droplets accumulate, which can easily form water blockage or vertical flow.

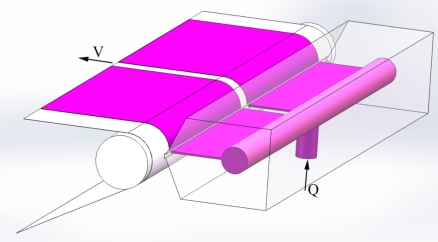

The schematic diagram of narrow slit extrusion coating is shown in Figure 1. A certain flow rate of slurry enters the internal cavity of the die from the feeding port of the extrusion head and forms a stable pressure. The slurry is finally sprayed out at the narrow slit outlet of the die head and coated on the foil. The coating roller rotates and moves forward with the foil. The coating is dried in an oven.

Picture 1: Schematic diagram of slit extrusion coating

Generally, the coating machine uses a servo motor with a precision planetary reducer to directly drive the coating roller. A servo motor converts the input signal into angular displacement or angular velocity output of the shaft, and the direction and speed of the shaft change with the voltage direction and magnitude of the signal (in pulse form). Therefore, the power fluctuation of the servo motor can also affect the coating accuracy. The ordinary single-phase thyristor rectifier power supply has a very high fluctuation capacity during low-speed coating, and this fluctuation will greatly reduce the coating quality.

At the same time, the battery slurry supply system can also cause unstable coating volume, because the low precision feeding valve, pneumatic diaphragm pump, and unstable pump pressure can cause the flow rate and pressure of the slurry at the mold inlet to be unstable, resulting in changes in the slurry flow rate at the narrow slit outlet of the mold.

In short, the main purpose of coating is to produce a uniform and consistent polar coating. The conditions for uniform and stable coating must meet the following conditions:

(1) The properties of the slurry are stable, without settling, and the viscosity and solid content remain unchanged;

(2) The slurry feeding supply is stable, forming a uniform and stable flow state inside the mold head or on the coating and transfer rollers;

(3) The coating process forms a stable flow field between the mold head and the coating roller within the coating window range;

(4) Stable foil walking, no belt sliding, severe shaking and wrinkles: tension and correction control.

Par conséquent, l’équipement de revêtement de boue d’électrode est devenu l’un des équipements clés pour le développement et la production réussis de batteries lithium-ion. La précision du revêtement de la machine de revêtement est inévitablement liée à la viscosité de la boue, de l'équipement et du processus de revêtement. La qualité du revêtement affecte directement la qualité de la batterie. Du point de vue du flux de processus, le revêtement est un processus clé dans la préparation des cellules de batterie, et du point de vue de la valeur de l'équipement, c'est également un processus clé dans la préparation des cellules de batterie (séries haut de gamme coûtant plus de dix millions). Du point de vue du contrôle non linéaire, il s’agit également d’un processus clé dans la préparation des cellules de batterie ; L'uniformité, la consistance, l'alignement, la stabilité à la cuisson, la diffusion de l'adhésif et la stabilité de la densité superficielle du revêtement y sont étroitement liés ; Les performances du revêtement simultané sont directement liées à des indicateurs pratiques tels que le coût et le taux de qualification.

Dans le processus de fabrication des batteries au lithium, des indicateurs clés tels que la capacité, le débit, la sécurité et la durée de vie de la batterie sont étroitement liés au processus de revêtement.

tel/Whatsapp: 0086-592-7161550

Scan to wechat: